We use the most efficient, environment-friendly processes to recycle waste plastics. We achieve the best possible industrial standards and produce PET flakes with less than 50 ppm PVC and our PP, HDPE, LDPE granules comply with their respective global industrial standards.

PP RAFFIA

PP AND PPCP

We crush and hot-wash PP waste (containers and paint buckets) to make PP (homo-polymer) and PPCP (co-polymer) granules using the latest two-stage granulators for industrial use. We process PP (homo-polymer) and PPCP (PP co-polymer) separately.

LDPE

We process post-consumer and factory waste low-density polyethylene (LDPE) bags, films and liners, etc. We procure these from various municipalities, scrap collectors and directly from various companies. The material is crushed and then washed using a four-step automatic washing line, which includes a hot-wash tank and friction washers. The washed LDPE is dried and finally sent to our granulation department to make high quality granules using the latest two-stage granulators. These granules are then used to make plastic bags, wraps and coatings, etc.

HDPE

We process post-consumer and post-industrial high-density polyethylene (HDPE) milk bottles, cans, pellets and drums, etc. We procure this HDPE waste from various municipalities, scrap collectors and directly from companies from across multiple sectors. This HDPE scrap is sorted according to types and colors, and the labels are removed using an automatic label-removal machine. The material is crushed before going into our four-step washing process, which includes a hot-wash tank and friction washers.

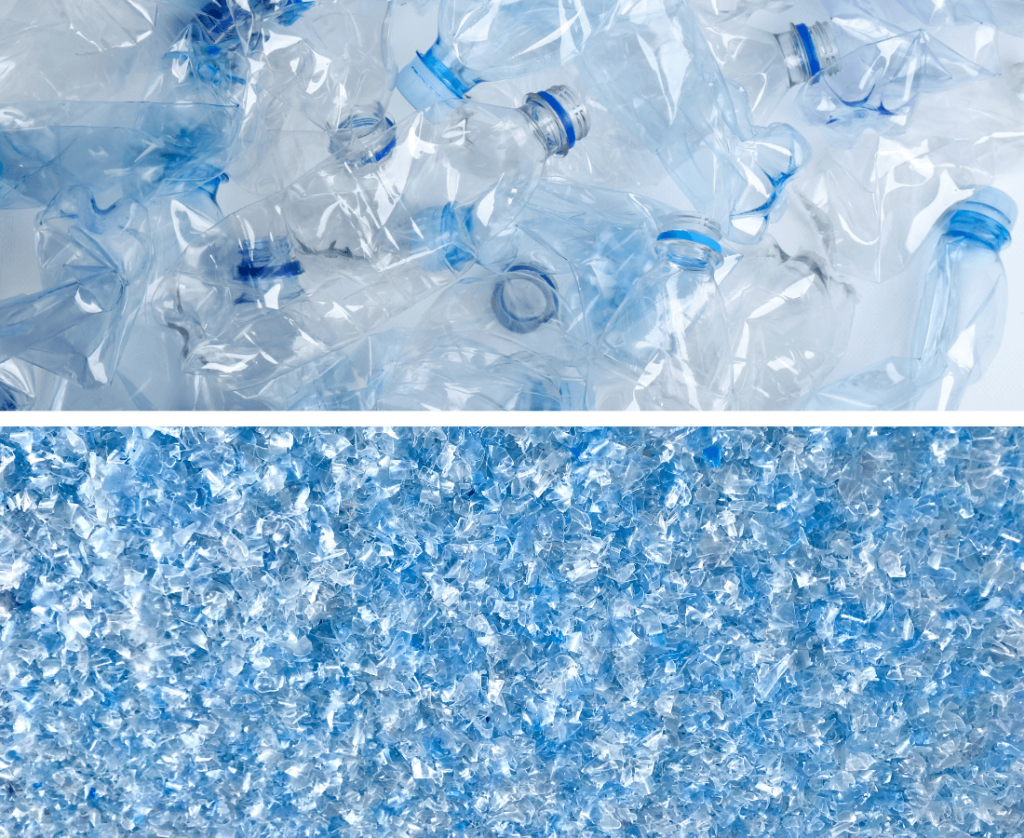

PET FLAKES

We use post-consumer and post-industrial PET bottles to make hot-washed PET flakes. We use automatic and manual sorting along with automatic label removers and PVC separators to produce PET flakes with less than 50 PPM of PVC. These flakes are used to make new PET bottles and containers, fiberfill for winter jackets, sleeping bags, and construction materials.

These flakes are also used to make industrial strapping, rope, upholstery fabrics, boat sails, automotive parts, and many other items. This recycling leads to reduction in the landfill mass and helps protect the environment through the reduction of carbon footprint and greenhouse effects, contributing to the UAE’s environment protection goals.